DNCA type ammonia synthesis catalyst is a new type of low temperature low pressure high activity ammonia synthesis catalyst which was developed and produced jointly by The Research Institute of Nanhua (Group) Company and our factory.

DNCA type ammonia synthesis catalyst is a new type of low temperature low pressure high activity ammonia synthesis catalyst which was developed and produced jointly by The Research Institute of Nanhua (Group) Company and our factory. Its performance has reached and exceeded ICI74-1 type ammonia synthesis catalyst. The composition, ratio and iron ratio of DNCA type ammonia synthesis catalyst are different from other ammonia synthesis catalysts in China. The product has the characteristics of easy reduction, low reduction temperature, good low temperature activity, strong resistance to pollution and heat, high mechanical strength, and is in the leading position among similar domestic and international products.

Chemical composition

The main component of the catalyst is Fe3O4, and contains appropriate amount of Cobalt, Al2O2, K2O, CaO and other special additives.

Physical property

*Appearance: Irregular particles with black gloss and magnetic.

*Granularity (mm): 1.5-3.0, 2.2-3.3, 3.3-4.7, 4.7-6.7, 6.7-9.4, 9.4-13.0 or other sizes customer request.

*Bulk density KG/L: 2.8-3.0, increases slightly as the particle size increases

* Poriness: 45%

*Specific area: 16.2 m2/g

Quality standard: HG/T3550-2013

Under laboratory conditions, when the particle size of the catalyst is 1.0 ~ 1.4mm, the loading volume is 2ml, the pressure is 15.0mpa, the airspeed is 3× 104HR-1, and the temperature is 415℃ (after 20h of heat resistance at 500℃), the outlet ammonia is not less than 14.0%. Strength: Wear particle size 1.0 ~ 3.0mm, wear rate < 2.0%, according to ASTM standard.

Property characteristic

a.Good activity at low temperature and low pressure

At the same temperature and pressure, the activity is significantly higher than that of A110 catalyst, especially at low temperature and low pressure, which was 10% ~ 15% higher than that of traditional A110 catalyst and 5% ~ 10% higher than that of A201 type ammonia synthesis catalyst.

b.Easy reduction low temperature

Its initial reduction temperature was about 30℃ lower than that of A110 catalyst, and the whole reduction temperature area was about 30℃ lower than that of A201, about 20℃ lower.

The reduction property as below:

Initial water outlet temperature: 300-330 ℃;

Large quantity water outlet temperature: 380-430 ℃;

Main reduction period: 425-450℃;

End reduction period: 480-490℃.

c.Good thermal stability

Add a special additive to improve the heat resistance and have good heat stability.

d.Good anti-pollution property

e.Ammonia synthesis catalyst is easy to be wet in the air, causing the precipitation of soluble potassium salt, which reduces the activity. Only after the catalyst is reduced to α-Fe by hydrogen, can it have the catalytic activity. Reduced catalysts, if exposed to air, rapidly oxidize and burn and lose their activity.

f.The reduced catalyst can be temporarily poisoned by oxygen-containing compounds such as carbon dioxide, carbon monoxide, oxygen and water vapor, and by oils, sulfur, phosphorus and arsenide, as well as by copper solution brought into the tower.

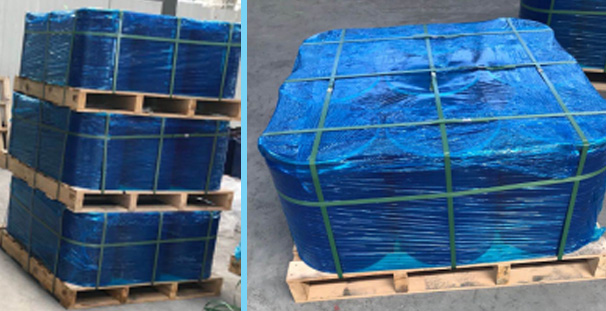

Metal/plastic bucket, 50kg/100kg/bucket

Copyright © Shandong Sanyi Group, Shandong Changtai Polymer Materials Co., Ltd.All Rights Reserved. Powered by MetInfo